Augmented Reality and Industry 4.0 Applications

When it comes to augmented reality, industry is one of the most promising fields of application. Companies are constantly looking for innovative solutions to improve the production process and make it more efficient and user-friendly, and AR presents numerous opportunities. Created for entertainment, this technology is entering more and more contexts. What makes it particularly interesting is its interactive nature, which opens the door to a unique and unprecedented productive creativity

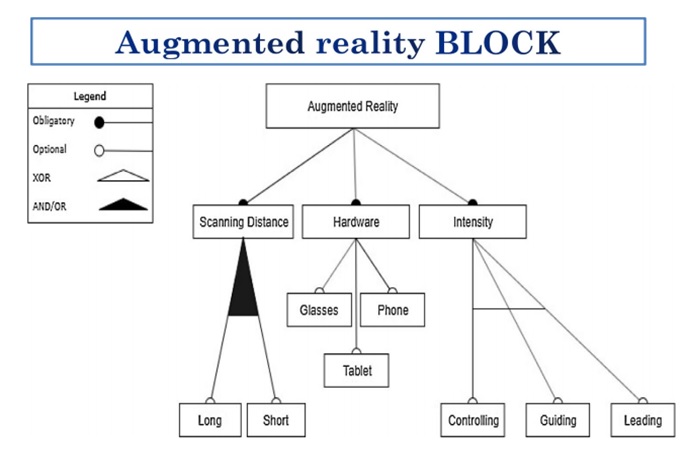

Augmented reality is a technology that augments the real environment overlaying it with the up-to-date digital. Information on the screen of your mobile device:

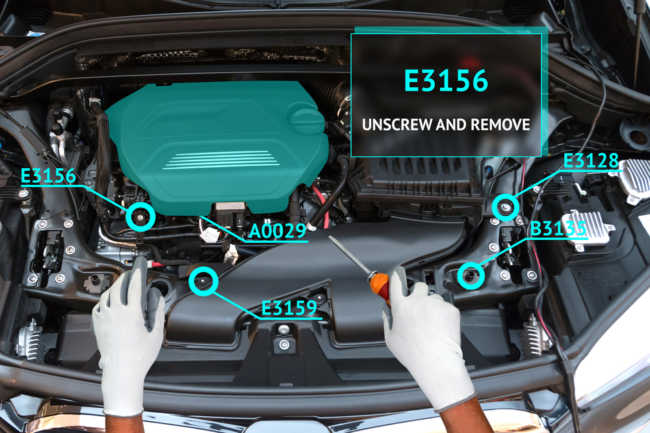

. The augmented reality app captures an image of the environment with the camera in a tablet, smartphone, head-mounted display, or AR smart glasses.

. The captured image is scanned to identify where to place additional information.

. The AR software requests for specific content to show to the user.

. The augmented reality application assembles an integral image of the physical environment and overlaid additional information.

. The augmented reality app captures an image of the environment with the camera in a tablet, smartphone, head-mounted display, or AR smart glasses.

. The captured image is scanned to identify where to place additional information.

The AR software requests for specific content to show to the user.

. The augmented reality application assembles an integral image of the physical environment and overlaid additional information.

. It is critical that all scene-processing operations occur as quickly and transparently as possible. Any time lags may confuse the end user and lead to various errors.

. Therefore, it is necessary to use high-quality AR hardware and software solutions that provide high performance.

. Vision picking systems are particularly advantageous because all operations can be performed using only AR smart glasses, without any additional input devices.

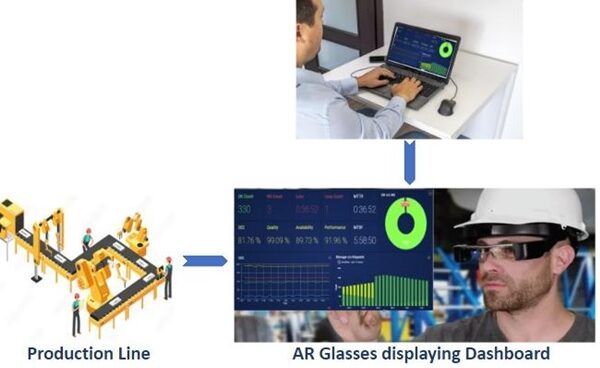

AR smart glasses are digital glasses, collecting data from internal and external sensors and providing relevant information to the user.

AR in Industrial Environments

AR can be used in infinite ways to improve the process in the Industry 4.0 but there are though some main areas that can be identified.Manufacturing

Imagine, how much AR can improve product design and development by monitoring production and helping to identify errors in the design in an early stage of the development process and, of course, also avoid these errors. This way it would drastically reduce the number of real prototypes needed, accelerate the production and process development and, thus, saving the company a lot of time and money.Support & Maintenance

What if engineers on-sight need support during production and maintenance? With AR you would have the possibility to provide support remotely. This makes it possible for highly specialized staff to be in more places at the same time. By making it visual for the engineers, they would exactly know what needs to be done without much hassle.Logistics AR can be of great help giving visual and clear guidance inside the buildings, like warehouses or plants. Especially if you are dealing with a big company you can make things easier by using AR to guide you through the complex to quickly find what you need. This way, even if you find yourself in a building you are not familiar with, you will be easily guided through it.

Sales and Presales

This is another area where AR can truly shine and be of great help to marketing and sales. With AR you can explain complex coherences in a visual way, so it will be easier to understand for your prospects. You can even show models of machines that are far too big or expensive to bring to a demonstration. With AR you can create a virtual showroom where your clients can see the product for themselves.Work protection and safety

This is another important area where AR can be of good use by showing workers what the potential hazards are or show emergency exit routes. Instead of using a map you will now have a strong visual aid to show the safety measures in their real environment which will help the wokers to act more quickly in case of an emergency.Implementation Process

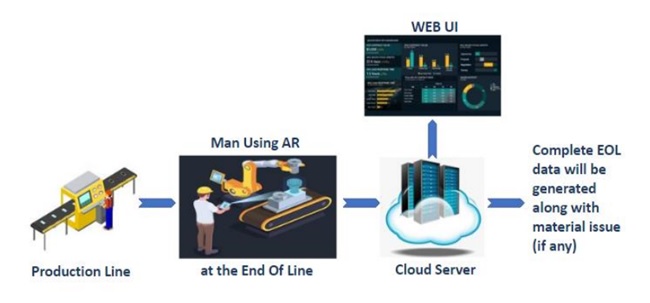

This section describes the process we use to work with the scope to implement the solution described. The AR Glasses, connected to the WiFi, will be provided to the member, who’ll be present at the End of production line. The AR Glasses will monitor the products simultaneously and will send the photo, of the product, to cloud server for inspection of any production error or material issue. After the data is sent to the cloud, server will examine it and revert it back. Later the man on site will get all the related information.

Solution Provided by Ingenious Techzoid

The goal of this software is to reduce the time consumed to track the data. This software will help us to centralize the data generated to a common server. The single most important (and most differentiating) feature of modern inventory management systems is automation.

Automated platforms give teams access to many things: real-time updates, alerts and reminders, and heightened control over their processes. The increased accuracy and real-time benefits of automation solutions have enabled teams to save time, decrease human error, and gain control and specificity over their work.

Cloud-based software ensures that team members can record and update data anytime, anywhere. Additionally, cloud-hosted systems allow teams to collaborate in real time, rather than waiting for the latest version to be sent out. Finally, find increased accuracy with cloud programs and ensure that there is only one record of the truth.

The benefits of augmented reality for product development :

. Shorter development time thanks to more effective planning and more extensive analysis Options.

. Reduced development costs .

. Can be used in the early stages of development.

. Increased safety, since risks are minimized.

. Improved collaboration through joint access to all relevant data and information in real time.

. Efficient product optimization through early identification and rectification of flaws and errors.

. Visualization of current projects for external departments, business partners, and customer.

Key Features

- maximizes our perceptive experience, allowing us to interact with information.

- contribute to the success and transformation of industrial production processes.

- 50% performance improvement when using AR solutions

- Speed up industrial operations.

- Increase production process efficiency.

- Reduce error occurrence.